Scaffold steel tube washer

Scaffolding installation is a key link of the whole construction project. Therefore, a proper scaffolding installation is crucial to ensure the construction safety and personal security of construction workers.

Then how to install a scaffolding system properly?

The installation steps of supported scaffolding are basically similar. The only difference is that whether U-head jacks are required. Generally, U-head jacks are required only when supported scaffolding are used for bridge and viaduct construction.

Let’s take the ringlock scaffolding for bridge construction as an example to introduce its installation process.

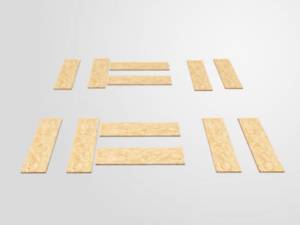

Place base plates properly.

Level the foundation and place base plates properly.

It should be noted that the foundation shall be flattened and compact during the scaffolding erection. In addition, reliable drainage measures must be taken to prevent the foundation from water soaking.

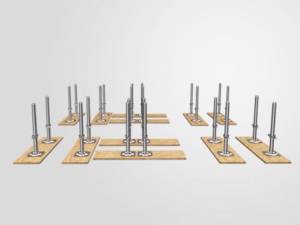

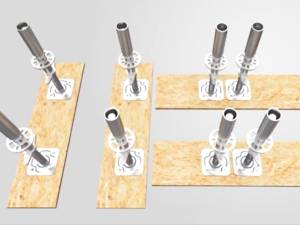

Put and fix jack base onto the base plates.

Put the adjustable jack bases to the designed position and fix them onto the base plate.

Sleeve the base collar into the jack base.

Put the sleeve part of the base collar upward on the adjustable jack base. Sleeve the lower part of the base collar into the jack base completely. Adjust the height of the jack base.

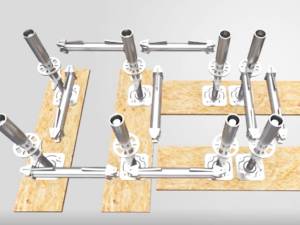

Connect two adjacent base collars with a ledger.

Wedge the ledger head into the ring plate. Make sure the hole on the wedge head is aligned with the mounting hole on the ring plate. Fix the ledger head and the base collar with a wedge pin through the mounting hole.

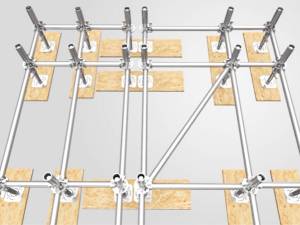

Connect the horizontal diagonal brace.

Connect two base collar ring plates in a horizontal diagonal line with a horizontal diagonal brace.

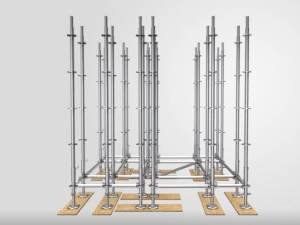

Insert the standard into the base collar.

Insert the standard into the base collar and fix it with a spigot pin. Make sure the standard end with a fixed drop forged joint pin upward.

Connect the second layer ledgers to the ring plate on the upper part of the standard.

Connect the second layer ledgers to the ring plate on the upper part of the standard as described in step 4.

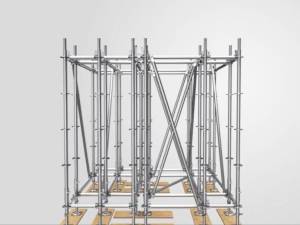

Connect the vertical diagonal brace.

Connect two adjacent standards at different horizontal lines with a vertical diagonal brace via diagonal brace head at both ends, thereby forming a triangle with the standard and the ledger and providing a more stable ringlock scaffolding system based on the theory of triangular stability.

Hook the steel plank onto the second layer ledgers.

Hook the steel plank onto the second layer ledgers and make sure steel planks are closely arranged and firmly fixed on ledgers.

Connect the second layer standards.

Insert the second layer standards to the upper part of the first layer standards then fix the standards with a spigot pin via the hole on the fixed drop forged joint pin. Repeat step 4 – step 9 until the height of the scaffold meets the construction requirements.

Install the U-head jack.

Insert the adjustable U-head jack into the standards and adjust its height.

During the construction, concrete, mortar and other contaminants often fall on and corrode scaffolds and steel planks. Although the scaffolds are treated with galvanized or PVC coated, which has excellent corrosion resistance, it will corrode and rust if not cleaned timely and maintained properly.

Therefore, timely cleaning and proper maintenance are required when the project is completed and scaffolds are disassembled to extend the service life of your scaffolding system.

Scaffold steel tube cleaning & maintenance