Vertical debris netting for scaffolding systems

search

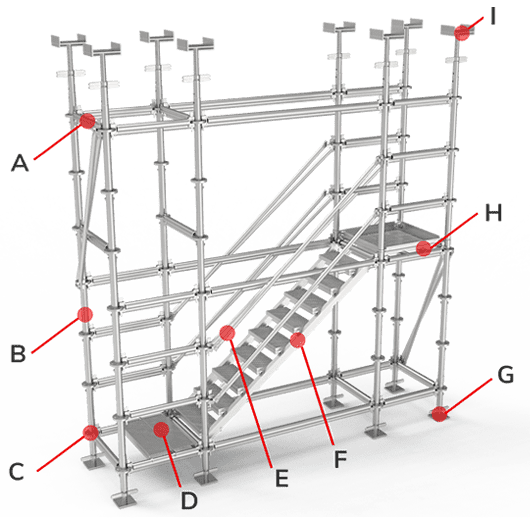

Ringlock scaffolding is a multi-purpose modular scaffolding system with ring lock joints. It is easy to install and operate with only one or two workers required. Workers can install, use and disassemble this temporary working platform quickly, thereby saving time and labor costs.

It can be flexibly assembled into modular scaffolding, birdcage scaffolding, suspended scaffolding, mobile scaffolding and supported scaffolding.

Characterized by high flexible installation angle, ringlock scaffolding can be used for structures with complex facades and shapes, such as the constructing, maintaining and decorating buildings with domes and spires, building ships and erecting tunnels and bridges.

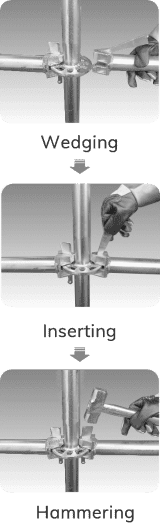

Assemble Process

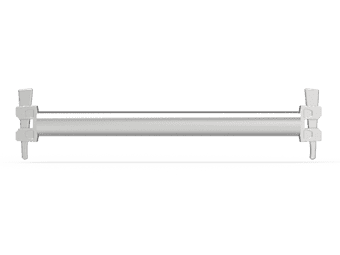

A: Ledger

It refers to the horizontal members of the ringlock scaffolding that are used to provide horizontal support for the load and steel planks. It consists of a steel pipe with a ledger head welded on both ends and two wedge pins. The wedge pin is used to fix the ledger head onto the ring plate firmly by inserting it into the ring plate through the hole on the ledger head. The ledger head is produced by cast steel wax molds.

| Item | Effective Length (mm) | Pipe Diameter (mm) | Pipe Wall Thickness (mm) | Weight (kg) | Minimum Tension (MPa) | Yield Limit (MPa) |

|---|---|---|---|---|---|---|

| RLS-L610 | 610 | 48.3 | 3.25 | 3.04 | 517 | 414 |

| RLS-L-920 | 920 | 48.3 | 3.25 | 4.13 | 517 | 414 |

| RLS-L-1070 | 1070 | 48.3 | 3.25 | 4.56 | 517 | 414 |

| RLS-L-1220 | 1220 | 48.3 | 3.25 | 5.20 | 517 | 414 |

| RLS-L-1520 | 1520 | 48.3 | 3.25 | 6.18 | 517 | 414 |

| RLS-L-1820 | 1830 | 48.3 | 3.25 | 7.31 | 517 | 414 |

| RLS-L-2130 | 2130 | 48.3 | 3.25 | 8.38 | 517 | 414 |

| RLS-L-2440 | 2440 | 48.3 | 3.25 | 9.57 | 517 | 414 |

| RLS-L-2740 | 2740 | 48.3 | 3.25 | 11.02 | 517 | 414 |

| RLS-L-3050 | 3050 | 48.3 | 3.25 | 11.96 | 517 | 414 |

| Notes: The sizes in the table are conventional sizes; other sizes are available upon request. |

||||||

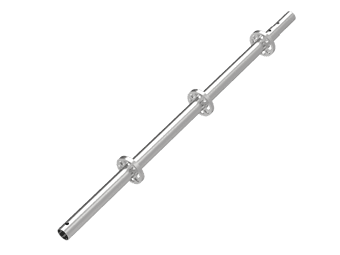

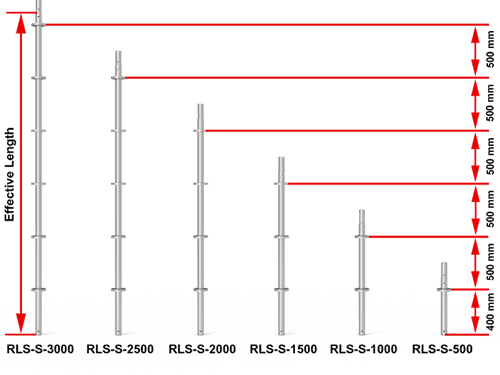

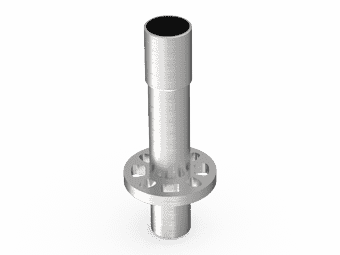

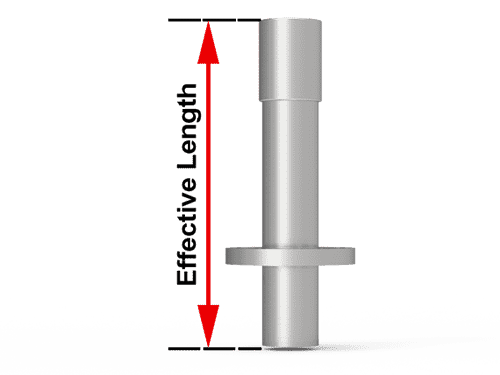

B: Standard

It refers to vertical members of the ringlock scaffolding system that are used to provide vertical support for the ringlock scaffolding system.

| Item | Effective Length (mm) | Pipe Diameter (mm) | Pipe Wall Thickness (mm) | Weight (kg) | Minimum Tension (MPa) | Yield Limit (MPa) |

|---|---|---|---|---|---|---|

| RLS-S-500 | 500 | 48.3 | 3.25 | 3.1 | 517 | 414 |

| RLS-S-1000 | 1000 | 48.3 | 3.25 | 5.5 | 517 | 414 |

| RLS-S-1500 | 1500 | 48.3 | 3.25 | 7.7 | 517 | 414 |

| RLS-S-2000 | 2000 | 48.3 | 3.25 | 10.1 | 517 | 414 |

| RLS-S-2500 | 2500 | 48.3 | 3.25 | 13.1 | 517 | 414 |

| RLS-S-3000 | 3000 | 48.3 | 3.25 | 15.0 | 517 | 414 |

C: Base Collar

It is a connection component of the ringlock scaffolding system. It is placed over the adjustable jack base and below the first layer standards.

| Item | Length (mm) | Weight (kg) |

|---|---|---|

| RLS-BC-300 | 300 | 2.43 |

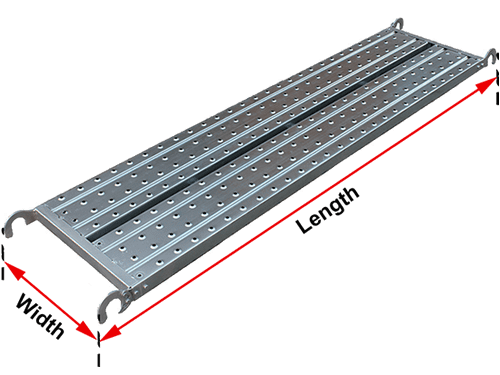

D: Steel Plank

It is a very important part of the ringlock scaffolding system. It is fixed on the ringlock scaffolding ledger for workers to walk on. Every corner is provided with a welded hook. Two or three beams are welded under the scaffold plank. Perforated plates are used to improve its anti-slip performance.

| Item | Length (mm) | Width (mm) | Thickness (mm) | Hook Diameter (mm) |

|---|---|---|---|---|

| RLS-SP-1500 | 1500 | 240, 420, 500 | 1.2, 1.5 | 43, 50 |

| RLS-SP-1800 | 1800 | 240, 420, 500 | 1.2, 1.5 | 43, 50 |

| RLS-SP-1530 | 1530 | 240, 420, 500 | 1.2, 1.5 | 43, 50 |

| RLS-SP-2400 | 2400 | 240, 420, 500 | 1.2, 1.5 | 43, 50 |

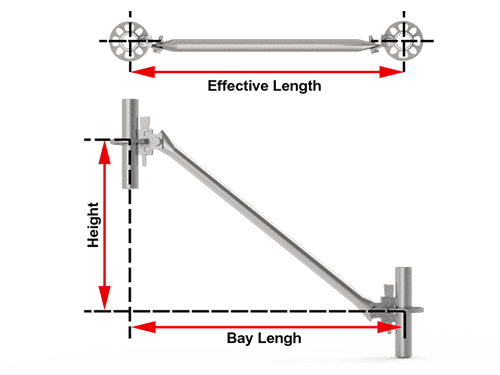

E: Diagonal Brace

It consists of a steel pipe with a diagonal brace head bolted on both ends and two wedge pins. The wedge pin is used to fix the diagonal brace head onto the ring plate firmly by inserting it into the ring plate through the hole on the diagonal brace head.

It is used to connect two adjacent ringlock scaffold standards at different horizontal lines via diagonal brace heads at both ends, thereby forming a triangle with the standard and the ledger and providing a more stable ringlock scaffolding system based on the theory of triangular stability.

| Item | Bay Length (mm) | Height (mm) | Pipe Diameter (mm) | Pipe Wall Thickness (mm) | Weight (kg) | Minimum Tension (MPa) | Yield Limit (MPa) |

|---|---|---|---|---|---|---|---|

| RLS-DB-920 | 920 | 2000 | 48.3 | 2.5 | 7.90 | 483 | 345 |

| RLS-DB-1070 | 1070 | 2000 | 48.3 | 2.5 | 8.22 | 483 | 345 |

| RLS-DB-1220 | 1220 | 2000 | 48.3 | 2.5 | 8.30 | 483 | 345 |

| RLS-DB-1520 | 1520 | 2000 | 48.3 | 2.5 | 8.33 | 483 | 345 |

| RLS-DB-1830 | 1830 | 2000 | 48.3 | 2.5 | 9.47 | 483 | 345 |

| RLS-DB-2130 | 2130 | 2000 | 48.3 | 2.5 | 9.87 | 483 | 345 |

| RLS-DB-2440 | 2440 | 2000 | 48.3 | 2.5 | 10.6 | 483 | 345 |

| RLS-DB-3050 | 3050 | 2000 | 48.3 | 2.5 | 12.17 | 483 | 345 |

F: Stair Stringer

Stair stringer is fixed on the ringlock scaffolding ledger to provide a ramp for workers to climb up to the upper access. It consists of rectangular steel pipes with hooks and anti-slip stair treads. Anti-slip stair treads provide superior anti-slip performance and ensure the safety of workers walking on it.

| Item | Length (mm) | Width (mm) | Height (mm) | Hook Diameter (mm) |

|---|---|---|---|---|

| RLS-SS-1800 | 1800 | 550, 860 | 1800, 2000 | 43, 50 |

| RLS-SS-1830 | 1830 | 420, 450, 860 | 1725, 1955 | 43, 50 |

| Notes: All sizes are available upon request. | ||||

G: Jack Base

It serves as the base of the ringlock scaffolding system. It helps keeping the ringlock scaffolding system stable by adjusting the height of the screw rod.

| Item | Overall Height (mm) | Effective Length (mm) | Base Plate Length (mm) | Base Plate Thickness (mm) |

|---|---|---|---|---|

| RLS-JB-600 | 600 | 460 | 140 | 5 |

| RLS-JB-800 | 800 | 530 | 140 | 5 |

H: Steel Toe Plate

It is a long steel plate set on the ledgers equipped with scaffold planks. It is almost as high as the instep, therefore, it is called steel toe board. It is mainly used to prevent objects from falling off when they roll to the steel toe board and prevent workers from falling.

| Item | Effective Length (mm) | Height (mm) |

|---|---|---|

| RLS-STB-830 | 830 | 180 |

| RLS-STB-1000 | 1000 | 180 |

| RLS-STB-1140 | 1140 | 180 |

| RLS-STB-1440 | 1440 | 180 |

| RLS-STB-1500 | 1500 | 180 |

| RLS-STB-1750 | 1750 | 180 |

| RLS-STB-2050 | 2050 | 180 |

| RLS-STB-2360 | 2360 | 180 |

| RLS-STB-2500 | 2500 | 180 |

| RLS-STB-2660 | 2660 | 180 |

| RLS-STB-2970 | 2970 | 180 |

I: U-head Jack

It is mainly used to connect ringlock scaffolding standards to provide strong support for applications where beams require support. U head is welded on the screw rod and a nut is provided, you may screw the nut to adjust the height of the screw rod.

| Item | Height (mm) | Screw Diameter (mm) | U-Head Size (L × W × H, mm) | U-head Plate Thickness (mm) |

|---|---|---|---|---|

| RLS-UHJ-600 | 600 | 32, 34, 36, 38 | 160 × 90 × 30 | 5 |

| RLS-UHJ-800 | 800 | 32, 34, 36, 38 | 160 × 90 × 30 | 5 |

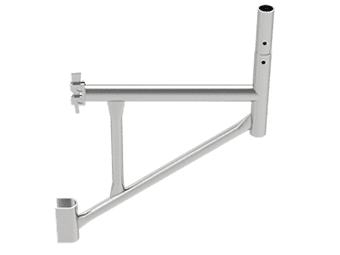

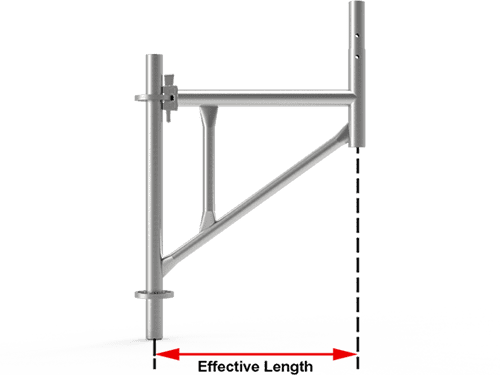

J: Side Bracket

It is an extension of the ringlock scaffolding system that is designed to extend or widen the reach with steel planks put on it. Together with steel planks, it forms a platform that can be used for storing building accessories.

| Item | Effective Length (mm) | Pipe Diameter (mm) | Pipe Wall Thickness (mm) | Weight (kg) |

|---|---|---|---|---|

| RLS-SB-320 | 320 | 48.3 | 3.25 | 1.71 |

| RLS-SB-400 | 400 | 48.3 | 3.25 | 4.71 |

| RLS-SB-610 | 610 | 48.3 | 3.25 | 5.90 |

| RLS-SB-650 | 650 | 48.3 | 3.25 | 6.10 |

| RLS-SB-740 | 740 | 48.3 | 3.25 | 6.59 |

| RLS-SB-880 | 880 | 48.3 | 3.25 | 7.45 |

| RLS-SB-920 | 920 | 48.3 | 3.25 | 8.56 |

| RLS-SB-1000 | 1000 | 48.3 | 3.25 | 9.04 |

| RLS-SB-1070 | 1070 | 48.3 | 3.25 | 9.33 |

| RLS-SB-1150 | 1150 | 48.3 | 3.25 | 10.42 |

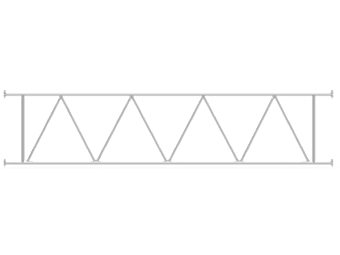

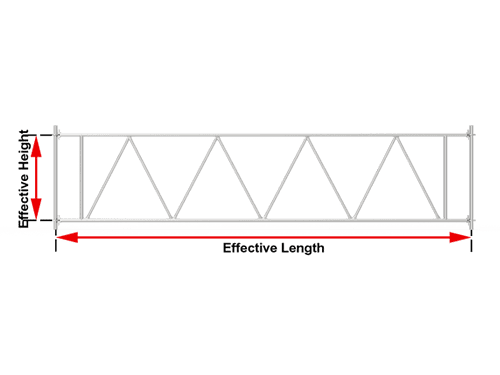

K: Lattice Girder

It is a horizontal member of ringlock scaffolding that allow for scaffolding over large spans or gaps to provide horizontal support for the load and steel planks.

| Item | Effective Length (mm) | Height (mm) | Weight (kg) |

|---|---|---|---|

| RLS-LG-2130 | 2130 | 500 | 24.15 |

| RLS-LG-2580 | 2580 | 500 | 28.20 |

| RLS-LG-3050 | 3050 | 500 | 31.90 |

| RLS-LG-4270 | 4270 | 500 | 45.24 |

| RLS-LG-4880 | 4880 | 500 | 49.85 |

| RLS-LG-5490 | 5490 | 500 | 56.00 |

| RLS-LG-6100 | 6100 | 500 | 62.87 |

| RLS-LG-6400 | 6400 | 500 | 63.35 |

| RLS-LG-8540 | 8540 | 500 | 94.00 |

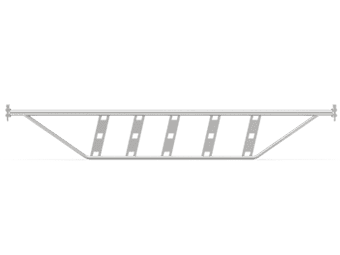

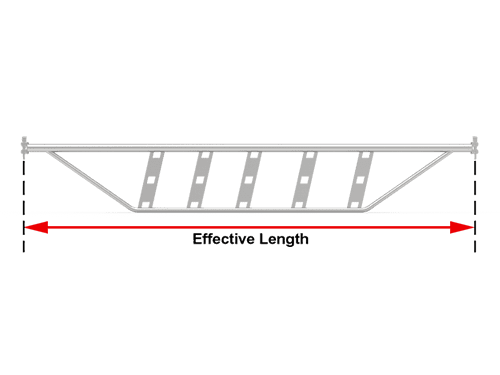

L: Truss Ledger

It is engineered to enable the working platform withstand higher working loads. Reinforced tubes and stiffener plates support the top tube to provide additional strength.

| Item | Length (mm) | Weight (kg) |

|---|---|---|

| RLS-TL-1000 | 1000 | 4.62 |

| RLS-TL-1500 | 1500 | 6.50 |

| RLS-TL-2000 | 2000 | 8.38 |

| RLS-TL-2500 | 2500 | 10.27 |

| RLS-TL-3000 | 3000 | 12.16 |